What if spaghetti could heal wounds or even regrow bones? This is no sci-fi dream but a groundbreaking innovation in nanotechnology. Scientists have created the world’s thinnest spaghetti nano spaghetti that’s not meant for your plate but for revolutionizing medicine and industry. Made from starch-rich flour, this nanofiber innovation offers a sustainable, efficient, and versatile solution to multiple challenges in healthcare and material science.

Let’s dive into how this invisible pasta came to be, its unique properties, and what the future holds for nanofiber science.

Why Make Nano Spaghetti?

Nano Spaghetti isn’t for your Bolognese; it’s an extraordinary achievement in material science. Nanofibers are ultra-thin strands with incredible uses, especially in medicine. These fibers can form highly porous mats that allow water and moisture to pass through while blocking bacteria, making them ideal for wound dressings. They can also serve as scaffolds for bone regeneration or even drug delivery systems, thanks to their microscopic size and adaptability.

“Nanofibers, such as those made of starch, show potential for use in wound dressings as they are very porous,” explains Professor Gareth Williams, one of the co-authors of this study. “In addition, nanofibers are being explored for their use as scaffolds to regrow tissue. They mimic the extracellular matrix, a network of proteins and other molecules that cells build to support themselves.”

Starch, the primary ingredient in nano spaghetti, is abundant, renewable, and biodegradable. However, conventional methods to extract and purify starch are resource-intensive, requiring significant energy and water. The researchers took a greener approach by skipping this step and starting directly with starch-rich flour.

How Did They Make the World’s Thinnest Spaghetti?

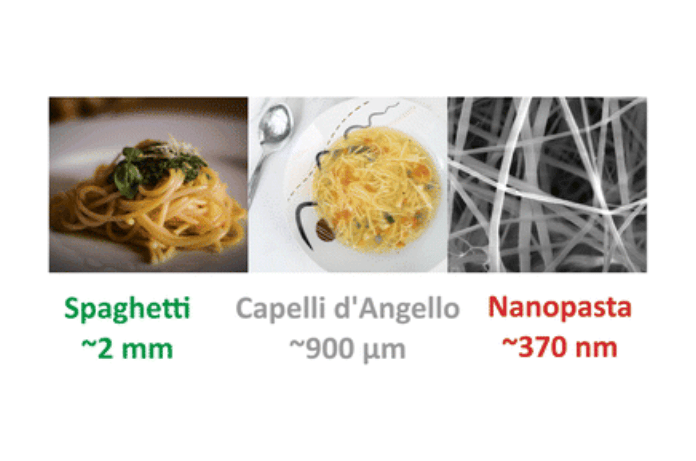

This innovation was achieved through a process called electrospinning. A technique where an electric charge pulls a liquid mixture into ultrafine threads. Traditional spaghetti is made by extruding a flour-water mixture through metal dies. This team used a high-voltage electrical charge to spin threads just 372 nanometers wide far thinner than a human hair or even some wavelengths of light.

Electrospinning wasn’t straightforward. Flour, unlike pure starch, contains impurities like proteins and cellulose that make the mixture more viscous and difficult to spin. To overcome this, the team replaced water with formic acid, a substance that breaks down the starch’s tightly packed helical structures, making it easier to spin. The acid evaporates during the process, leaving behind the ultrathin fibers.

“It’s literally spaghetti but much smaller,” says Dr. Adam Clancy, co-author of the study. “We’ve shown that a simpler way to make nanofibers using flour is possible. This could open doors to more sustainable ways of producing nanomaterials.”

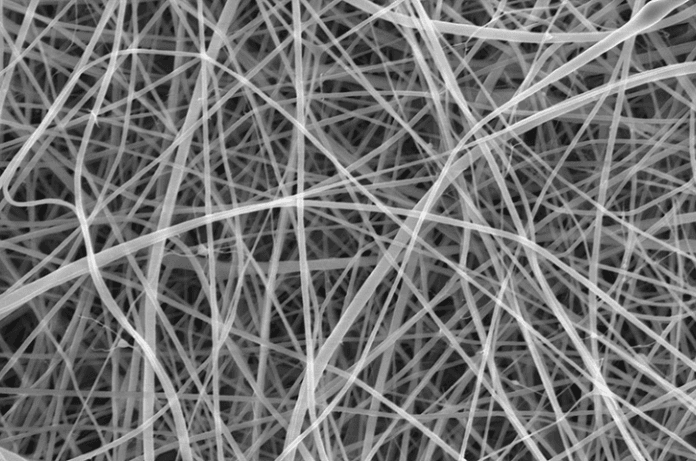

The result was a mat of nanofibers visible to the naked eye. However, the individual strands were too small to be captured by standard cameras or microscopes. Their width was measured using a scanning electron microscope and confirmed their astonishingly tiny size.

Challenges in Creating Nano Spaghetti

Making nano spaghetti isn’t without its hurdles. The researchers had to carefully adjust the mixture’s composition and temperature over several hours. “I really enjoyed the iterative process of adjusting the variables and observing how this changed the mixture,” says lead author Beatrice Britton, who conducted the study as part of her master’s degree at UCL. “It was a lot of trial and error — I didn’t think I would form fibers, but I did.”

The Practical Applications of Nano Spaghetti

Nano spaghetti isn’t meant for the dinner table, its potential applications are vast:

- Wound Healing: Nano Spaghetti mats are highly porous, allowing moisture and oxygen to promote healing while keeping bacteria out.

- Bone Regeneration: The fibers can act as scaffolds for tissue growth, mimicking natural structures in the body.

- Drug Delivery: Their microscopic size and biocompatibility make them ideal for targeted drug delivery systems.

- Eco-Friendly Materials: By starting with flour, the team has demonstrated a more sustainable way to produce nanofibers compared to traditional methods.

Starch, as Dr. Clancy points out, is the second-largest source of biomass on Earth, behind cellulose. This makes it an attractive and eco-friendly resource for developing advanced materials.

A World Record in Pasta Innovation

This ultrathin pasta is more than a scientific novelty, it’s a record-breaker. At 372 nanometers wide, it’s 1,000 times thinner than traditional Sardinian pasta, su filindeu (“threads of God”), which is handmade and measures about 400 micrometers.

What’s Next for Nano Spaghetti?

The team’s work is only the beginning. Future studies will focus on understanding the properties of nano spaghetti, including how it interacts with cells, how quickly it disintegrates, and whether it can be scaled up for industrial applications.

Despite its revolutionary potential, nano spaghetti isn’t likely to appear in kitchens. “It would overcook in less than a second before you could take it out of the pan,” jokes Professor Williams.

Big Innovations from Tiny Threads

Nano Spaghetti is a testament to the power of nanotechnology. By transforming a simple ingredient like flour into something as innovative as nanofibers, scientists have opened the door to sustainable solutions in medicine and beyond.

While it won’t replace your fettuccine anytime soon, this microscopic pasta proves that big advancements can come from the tiniest threads.