Imagine a disaster site, full of collapsed buildings, and the survivors were struggling beneath layers of debris. Traditional search-and-rescue teams struggle to navigate the dangerous terrain, and sending in bulky or humanoid robots proves ineffective. Now, there is a solution to the world’s biggest challenges. Hundreds—perhaps thousands—of small, agile robots, working together like an intelligent swarm of ants, slipping through the rubble. Furthermore, these robot swarms could map out the wreckage and relay critical information to saviors.

This vision is no longer science fiction. In the real world today, these robot swarms could help in rescue tasks. Let’s dive into the details of the story.

Back-drop of Robot Swarms Idea

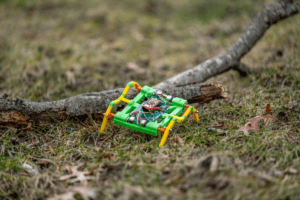

In a groundbreaking development, researchers at Tufts University have developed a new class of soft-jointed robots designed and developed on a 3D printer to operate collaboratively in large numbers. These compact robots, approximately the size of a palm, promise to revolutionize fields such as search and rescue. The cost-effective robots are efficient in environmental monitoring, defense, disaster, and landmine clearance.

Assistant Professor Markus Nemitz spearheaded the project and has long envisioned deploying swarms of small robots to tackle complex tasks in challenging environments.

His prior work focused on developing algorithms to control large assemblies of robots, enabling them to share information and adapt their behavior based on evolving conditions. However, the absence of practical robotic systems to implement these algorithms led him to address this gap.

The primary obstacle to realizing such robot swarms has been the extremely costly, and time-consuming manufacturing process. That too manufacturing hundreds or thousands of robots consumes tons of golden days.

Design of Soft-jointed Robots

The research team overcame this challenge by designing a robust robot that can be almost entirely fabricated on a 3D printer within just a few hours. This approach not only reduces production costs but also optimizes the manufacturing process. Thereby, making it feasible to produce large numbers of robots rapidly.

The printer is capable of dispensing multiple materials. It can dispense both semi-soft and soft components that are built simultaneously. Electronics are added manually in the middle of the print, but this step can be automated too.

The robots’ design incorporates both soft and rigid components, enhancing their resilience in unpredictable environments. Unlike fully rigid robots, these machines feature soft joints that allow for more fluid motion and adaptability to uneven terrains. This design enables them to navigate over rocks, sand, and steep rises, maintaining functionality even after impacts or compression.

Our flexible and compact robots can handle many different environments. Drop our robots from a plane or put them under a wheel. Still, They will function their program, said Nemitz.

Compatibility of the Tiny and Flexible Robots

Like the limbs of a mammal or retile that have bone structures connected by softer cartilage-lined joints, the limbs of the robot are made of semi-soft links. This allows some play in the motion beyond a single plane of rotation in the robot’s joints. By integrating materials with different levels of softness into its linkages, the robot enhances its durability and resistance to physical impacts

When landing on uneven and unpredictable terrains, the fully rigid robots, some of them are quite agile, still have to make sudden multiple rapid corrections in more than one limb to stay upright. The Tufts-developed robots with soft joints have a more fluid pattern of motion when walking over terrain. These patterns help the tiny robots to easily adapt to surface irregularities.

The potential applications for these robot swarms are vast. In disaster scenarios, they could be deployed to search for survivors in areas inaccessible to humans or larger machines. Environmental agencies might use them to monitor pollution levels or track wildlife in remote regions. In agriculture, swarms could assess soil conditions, manage pests, or monitor crop health, providing farmers with real-time data to optimize yields.

The Tufts University research team is already exploring specific applications, including landmine clearing and environmental monitoring, such as tracking the changing conditions and position of glaciers. The adaptability and resilience of these robots make them well-suited for such tasks, where conditions are harsh and unpredictable.

Conclusion

In conclusion, this innovation represents a powerful leap forward in robotics, as well as disaster and environment management. This combines advanced manufacturing techniques with sophisticated design to create machines capable of working together to accomplish tasks beyond the reach of individual robots.

As research progresses, these 3D-printed robot swarms could become invaluable tools across a range of industries, addressing challenges from disaster response to environmental conservation.