In the healthcare industry, the introduction of wearable technology has shown in a new era of patient care. The latest remarkable breakthrough in this field is the development of a flexible, self-powered sensor. It is capable of simultaneously measuring temperature and physical strain. This flexible sensor offers a more comprehensive approach to wound monitoring. It is achieved through the use of laser-induced graphene (LIG).

Researchers say LIG holds the potential to revolutionize how healthcare professionals track the healing process. Let’s see what the research has for us to learn.

The Challenge of Simultaneous Signal Measurement

Traditional self-powered wearable sensors often face the challenge of differentiating between various signals, such as temperature changes and physical strain, when they occur simultaneously. Accurate differentiation between these signals is crucial for effective healthcare monitoring. This is particularly true in wound care, where both temperature changes and physical deformation or strain provide pivotal information about the healing process.

The Role of Laser-Induced Graphene (LIG)

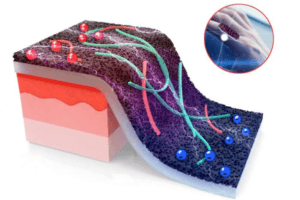

Laser-induced graphene (LIG) is a two-dimensional (2D) material produced by heating carbon-rich materials, like certain plastics or wood, with a laser. This process reportedly converts the surface into a graphene structure, allowing for the direct “writing” of graphene patterns onto the material. This method is not only simple and scalable but also enables the creation of complex graphene designs for electronics, sensors, and energy devices. These designs are very important for advanced sensor applications.

Researchers from Penn State and China’s Hebei University of Technology have discovered that LIG exhibits thermoelectric properties a finding that adds a new dimension to its applicability. Thermoelectric materials can convert temperature differences into electrical voltage and vice versa. Thereby making these materials valuable for energy harvesting and temperature sensing.

By leveraging this property, the researchers developed a sensor that can decouple temperature and strain measurements, providing accurate and separate readings for each parameter.

Now doctors could leverage this material to get a clear picture of the healing process and identify issues like inflammation beforehand.

For the first time in the history of laser-induced graphene, we have reported LIG having thermoelectric capabilities, said Cheng.

LIG sensors are self-powered as their thermoelectric nature can generate electricity from temperature differences. This capability makes them ideal for continuous monitoring in hospitals. In addition, the researchers are already working on a wireless system for these sensors. This makes the future even more brighter in the field of patient care. Healthcare professionals can monitor the sensor data—like temperature or strain—remotely.

Implications for Wound Monitoring

In wound care, monitoring both temperature and strain is essential. Temperature changes can indicate inflammation or infection, while strain measurements can reveal the degree of wound closure and tissue regeneration.

The new LIG-based sensor is highly sensitive and can detect temperature changes as small as 0.5 degrees Celsius. And the sensor can stretch up to 45%, allowing it to conform to various wound shapes and surfaces. This flexibility ensures that the sensor can maintain close contact with the wound site, providing continuous and accurate monitoring.

The research team says that healthcare providers can gain real-time insights into the wound-healing process by integrating this sensor into a bandage. Early detection of complications such as infection or impaired healing can lead to timely interventions. Also enhances healing and reduces the risk of chronic wounds.

“The porous structure of this flexible material creates a lot of small spaces. These gaps will allow the material to interact with wound surroundings in a very sensitive way,” said Cheng. Furthermore, the sensitive nature of this thermoelectric material makes it well-suited for interfacing with human soft tissues.

Conclusion

The discovery of the thermoelectric properties of LIG opens routes for its application beyond wound monitoring. The flexibility, sensitivity, and self-powered nature of this sensor make it a promising tool in the pursuit of personalized healthcare and environmental monitoring. Ongoing research aims to explore these applications further and to refine the sensor’s capabilities for integration into various platforms.

In conclusion, the development of a flexible, self-powered sensor using laser-induced graphene (LIG) material that can simultaneously and separately measure temperature and strain. It provides a more comprehensive understanding of wound healing. Furthermore, paving the way for improved patient care and the potential for broader applications in health and environmental monitoring.