What does it take to set a new benchmark in power generation? Harbin Electric Corporation has delivered the answer with the world’s first 660 MW high-efficiency ultra-supercritical circulating fluidized bed (CFB) power generation unit. Recently completing a 168-hour full-load trial operation, this technological feat, located in Binchang, China, is setting unparalleled standards in energy efficiency and ecological innovation.

The Binchang Project: A Model for Sustainability and Efficiency

Endorsed by the Ministry of Science and Technology and the National Energy Administration, the Binchang Project is more than just a power plant. It embodies a vision of sustainable coal-powered energy. By combining solid waste and mine water utilization with geological restoration and land reclamation, the project is a cornerstone of ecological restoration efforts in the Yellow River Basin.

When fully operational, the first phase of the project will annually convert approximately 2 million tons of low-calorific value coal and inferior fuels like coal slime and gangue. It will also utilize 2 million tons of mine water, producing 6 million GJ of heat to meet the heating and industrial steam needs of Binzhou City. Beyond this, the project will stabilize the regional power grid, address local power shortages, and drive socio-economic growth in the area.

Engineering Prowess: Core Components at the Forefront

Harbin Electric Corporation has designed and manufactured the boiler, turbine, and generator for the Binchang Project, creating a trifecta of engineering excellence.

- CFB Boiler: Developed by Harbin Boiler Company, this ultra-supercritical boiler achieves record-breaking parameters with ultra-low emissions, ultra-high performance, and ultra-low energy consumption. Its main steam pressure reaches an astonishing 29.3 MPa—equivalent to the weight of four adults standing on a nail-sized section of pipe. With a main steam temperature of 605°C and a reheat steam temperature of 623°C, it has set new global benchmarks. The boiler’s desulfurization efficiency of 95% ensures ultra-low emissions, making it an industry leader in environmental performance.

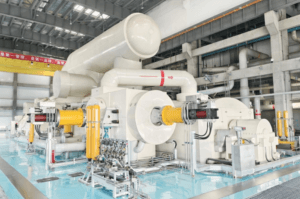

Image: Steam Turbine Generator | Credit: Harbin Turbine Company - Turbine: The ultra-supercritical indirect air-cooled reverse-flow turbine, designed by Harbin Turbine Company, is a 660 MW-class powerhouse. Its advanced once-through reheat, single-axis, three-cylinder, two-exhaust design ensures exceptional thermal performance and flow efficiency, reinforcing its status as a pinnacle of turbine technology.

- Generator: Harbin Electric Machinery Company’s wide-load high-efficiency generator combines high output with minimal energy loss. Its design supports challenging operational conditions, such as deep peak shaving and negative-sequence operation, ensuring optimal performance under varying demands.

Aligning with China’s Vision for the Future

This breakthrough in ultra-supercritical CFB power generation marks a milestone in China’s 13th Five-Year Plan, reflecting the nation’s ambitions for high-parameter, large-capacity, and energy-efficient technologies. Harbin Electric Corporation has integrated advanced engineering and research, collaborating with leading institutions like Tsinghua, Xi’an Jiaotong, Zhejiang, and Chongqing universities to achieve this feat. These partnerships enabled the scaling of ultra-high-parameter CFB boilers to a remarkable 660 MW capacity, setting a precedent for global energy advancements.

The boiler, with its cutting-edge technology, has redefined what’s possible in energy production. Its main steam and reheat temperatures, combined with unparalleled pressure parameters, represent a leap forward in efficiency, environmental sustainability, and operational excellence.

Impact Beyond Technology

The Binchang Project is a game-changer not only in power generation but also in ecological restoration. By recycling 2 million tons of mine water annually and producing sustainable heat energy, it addresses pressing environmental and energy challenges. The ultra-supercritical technology ensures low emissions and high efficiency, setting a model for future coal-powered projects worldwide.

The project also meets critical local needs, such as stabilizing power supply and supporting industrial and residential heating. Its innovative approach to resource utilization and environmental restoration demonstrates a path forward for energy projects worldwide.

Ushering in a New Era of Power Generation

The successful operation of the world’s first 660 MW ultra-supercritical CFB power unit is a triumph of innovation and engineering. Harbin Electric Corporation has not only filled a critical gap in global energy technology but also cemented its role as a pioneer in sustainable, high-capacity power solutions. This project serves as a beacon for future advancements, heralding a new era of ultra-supercritical CFB technology that balances efficiency, sustainability, and industrial growth.

With the Binchang Project setting the stage, Harbin Electric Corporation continues to lead the way in meeting the challenges of an evolving energy landscape. Its commitment to innovation ensures a future where power generation aligns seamlessly with ecological and economic priorities.