In recent years, there has been a significant push towards using sustainable materials in various industries to minimize environmental impacts. One such area is the railway industry, where the use of recycled materials for infrastructure components has gained attention. Railway sleepers, traditionally made from concrete or wood, have become a key focus for innovation. The study conducted by Heikki Luomala, Rami Halmel, and Ilari Jönkkäri explores the potential of using recycled plastics, specifically ABS (Acrylonitrile Butadiene Styrene) and LPB repulping reject plastics, in the production of railway sleepers. This research aims to assess the viability of these materials as alternatives to traditional sleepers, focusing on their mechanical properties, environmental benefits, and potential challenges.

Understanding Railway Sleepers and Their Importance

Railway sleepers are essential components of railway track systems. They serve as a support structure, holding the rails in place and distributing the load from trains. Traditionally, railway sleepers have been made from wood, concrete, or steel. Each material has its advantages and disadvantages. Concrete sleepers, for example, are durable and long-lasting, but they are heavy and require significant energy during production. On the other hand, wood sleepers are lighter but have a shorter lifespan and are more susceptible to environmental degradation. As a result, the railway industry is seeking alternative materials that can provide similar or better performance while being more environmentally friendly.

Recycled Plastics: A Sustainable Alternative

The study by Luomala, Halmel, and Jönkkäri highlights the potential of using recycled plastics in the production of railway sleepers. Plastics, particularly ABS and LPB repulping reject, are commonly incinerated or discarded as waste. Recycling these plastics for use in railway sleepers offers multiple environmental benefits. By diverting these materials from landfills or incineration, the railway industry could contribute to a circular economy, reducing waste and decreasing the environmental footprint of track construction.

Recycled plastics, particularly ABS, have several advantageous properties that make them suitable for use in sleepers. ABS is known for its strength, stiffness, and resistance to environmental factors, making it a durable choice for railway sleepers. Moreover, the mechanical properties of recycled ABS were found to be relatively similar to those of virgin ABS, ensuring that the sleepers maintain a high level of performance. The study demonstrated that recycled ABS is approximately three times stronger and stiffer than LPB repulping reject, making it a more promising material for railway sleepers.

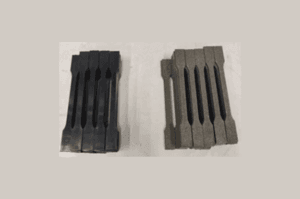

Mechanical Testing and Results

The mechanical properties of both ABS and LPB repulping reject plastics were tested as part of the study. The results showed that sleepers made from recycled ABS are moderately suitable for use across various track types, with particular advantage for freight traffic lines. In contrast, sleepers made from recycled LPB repulping reject showed excessive softening in higher summer temperatures, rendering them unsuitable for use in their current form. While additives could potentially increase the softening point of the LPB repulping reject plastics, this was beyond the scope of the study.

For example, Liu et al. (2021) found that rectangular composite sleepers, a form of plastic sleeper, exhibited a lateral resistance of only 4.85 kN, compared to 13.61 kN for concrete sleepers with more complex shapes. The lower lateral resistance of plastic sleepers raises concerns about track stability, as it may lead to track buckling, especially in continuously welded rail systems. The study conducted by researchers Luomala, Halmel, and Jönkkäri confirmed this issue, as the lightweight nature of plastic sleepers can reduce the lateral resistance of the track. This could lead to challenges in maintaining track integrity, especially under heavy traffic conditions.

Environmental Benefits: Reducing Greenhouse Gas Emissions

The use of recycled plastics for railway sleepers also offers significant environmental benefits, particularly in terms of reducing greenhouse gas (GHG) emissions. The study assessed the potential emission reductions associated with replacing traditional concrete sleepers with recycled plastic sleepers. For instance, if all LPB repulping rejects recycled in Finland during a given year were used to manufacture sleepers instead of being incinerated, it could lead to a reduction of 3,610 tCO2e (tons of CO2 equivalent) in emissions. This reduction accounts for emissions avoided throughout the material’s life cycle, from production to disposal.

Furthermore, if both ABS and LPB repulping reject plastics were mechanically recycled and used as materials instead of incineration, an annual emission reduction of 24,200 tCO2e could be achieved. This highlights the significant potential for the railway industry to contribute to climate change mitigation by embracing recycled plastic materials. The reduction in GHG emissions would be especially notable when considering the avoided energy costs associated with incinerating these plastics for heat recovery.

Design Flexibility and Potential Applications

The use of recycled plastics for railway sleepers also offers greater design flexibility compared to traditional materials. Plastic sleepers can be molded into various shapes, allowing for innovative designs that can improve the performance of the track. For example, the KLP sleeper, made from recycled plastic, has been shown to enhance lateral resistance, improving the overall stability of the track. This flexibility can lead to cost-effective solutions for different types of tracks, including those used for freight, high-speed, and urban rail systems.

Moreover, the lightweight nature of plastic sleepers makes them easier to handle during installation, reducing labor costs and the need for heavy machinery. This makes plastic sleepers particularly suitable for use in remote or difficult-to-access areas where traditional concrete sleepers would be challenging to transport and install. Despite the benefits, the reduced lateral resistance of plastic sleepers remains a concern that needs to be addressed through further research and development.

Challenges and Future Directions

While the study demonstrates the promising potential of recycled plastics for railway sleepers, there are several challenges that need to be addressed. One of the key concerns is the long-term durability of plastic sleepers, particularly their resistance to UV radiation. The effects of prolonged exposure to sunlight on the strength and stability of recycled plastic sleepers have not been fully explored in the study. Future research will need to investigate the UV resistance of these materials and identify potential solutions, such as additives or coatings, to enhance their longevity.

Additionally, the issue of microplastic generation due to mechanical abrasion from plastic sleepers is another area that requires further study. As the plastic sleepers wear down over time, they could contribute to the production of microplastics, which could have adverse environmental effects. Addressing these concerns will be essential before the widespread adoption of plastic sleepers in the railway industry.

Conclusion

This research provides valuable insights into the use of recycled plastics, specifically ABS and LPB repulping reject, for the production of railway sleepers. While ABS emerges as a more promising material due to its superior strength and stiffness, LPB repulping reject presents challenges due to its tendency to soften in warmer temperatures. The potential environmental benefits of using recycled plastics for railway sleepers are significant, including substantial reductions in GHG emissions and reduced waste. However, challenges related to the long-term durability of plastic sleepers and the risk of microplastic generation need to be addressed in future research.

With continued innovation and testing, the use of recycled plastics in railway sleepers could become a key component of sustainable rail infrastructure. By embracing these materials, the railway industry has the opportunity to reduce its environmental footprint while improving the performance and cost-effectiveness of its infrastructure.