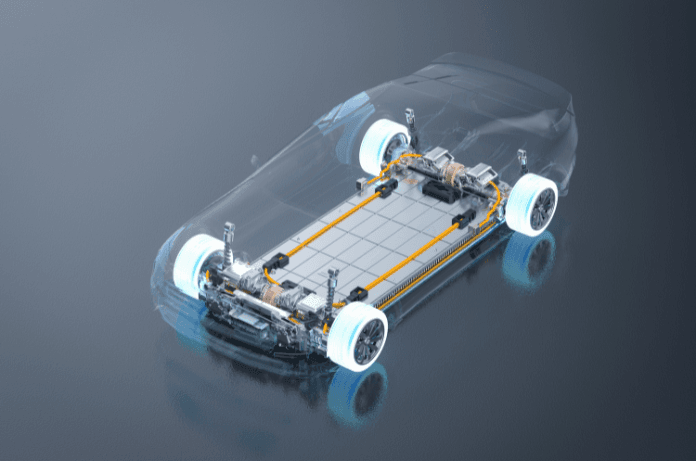

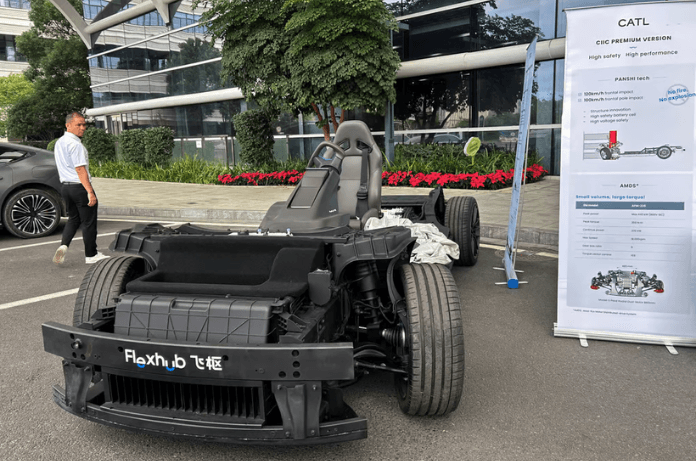

The electric vehicle (EV) market is witnessing a seismic shift, and at the epicenter of this transformation is China’s Contemporary Amperex Technology Co., Limited (CATL), the world’s largest EV battery maker. This giant EV battery maker has unveiled a groundbreaking innovation – a cutting-edge EV chassis, aptly named “Panshi” (which translates to “bedrock” in Chinese). Panshi chassis, the world’s first ultra-safe skateboard chassis. It is set to redefine safety standards, streamline production timelines, and lower the barriers to entry for new EV players globally.

But what makes this new chassis so extraordinary? Let’s explore how CATL’s big innovations are reshaping the future of EV manufacturing.

Safety First: The Bedrock of Innovation

Safety is the hallmark of CATL’s Panshi chassis. During its official launch, CATL stunned the automotive world with an audacious claim: the Panshi chassis can withstand a 120 km/h (75 mph) frontal impact without catching fire or exploding. To put this into perspective, the commonly used China New Car Assessment Program (C-NCAP) sets the standard frontal impact test speed at 56 km/h.

The bedrock chassis introduces a groundbreaking 3-dimensional biomimetic tortoise shell structure. The body and energy unit framework are integrated and deeply coupled in this rigid structure providing the energy unit with unstoppable protection.

In addition, the use of submarine-grade hot-formed steel with a strength of 2000MPa, aerospace-grade aluminum alloy with a strength of 600MPa, and multiple barrier structures additionally enhance the chassis’ rigidity, making it virtually impervious.

In addition to its unparalleled safety features, the Panshi platform delivers an impressive 1,000-kilometer (621 miles) range per charge, ensuring long-distance travel capabilities without compromising safety standards. By balancing exceptional durability with industry-leading performance, the platform solidifies CATL’s commitment to advancing EV technology while addressing critical safety concerns.

“Due to the extremely high crash speed and intensity, there has been no previous instance of any new energy vehicle daring to challenge a 120 km/h frontal pole impact test,” said Ni Jun, CATL’s chief manufacturing officer. This bold move not only sets a new safety benchmark but also positions CATL as a pioneer in ensuring passenger safety in electric vehicles.

Panshi Chassis: Production Efficiency Redefined

One of the most remarkable features of the Panshi chassis is its fast mass-production timelines. Traditional EV manufacturing can take upwards of 36 months, but CATL’s innovative platform slashes this timeline to just 12–18 months.

This leap in efficiency is attributed to the bedrock chassis’s unique design. It integrates the battery directly into the vehicle’s frame. Such platforms, often referred to as “skateboard chassis,” house all key components batteries, motors, controls, and suspensions in a single, flexible structure.

Robin Zeng, CATL’s chairman, emphasized the financial benefits of this innovation in a press conference: “The Panshi technology could reduce the cost of developing a new EV to as little as USD 10 million, allowing niche automakers to break even by selling just 10,000 cars annually.”

A Platform for Premium Automakers

CATL envisions the Panshi chassis as a game-changer for premium automakers looking to accelerate development and cut costs. The first EV brand to adopt this revolutionary platform is Avatr, co-owned by CATL, state-owned Changan Auto, and technology giant Huawei. While the launch date of the Avatr model based on Panshi has not been disclosed, the collaboration signals a significant step toward widespread adoption of this technology.

Beyond Avatr, CATL has reportedly showcased the Panshi platform to luxury automakers like Porsche and investors in the United Arab Emirates (UAE) eager to create local EV brands.

Global Market Dominance and Strategic Collaborations

CATL’s dominance in the EV battery market is indisputable, holding a staggering 37% global market share, according to SNE Research. With the latest revolutionizing Panshi chassis, CATL not just launched innovative auto mechanisms but unearthed the trillion Yaun market.

The company’s innovation in integrating batteries into vehicle chassis began in 2020, and since then, CATL has forged partnerships with notable automakers like VinFast, BAIC, and Neta to develop models based on this technology. These collaborations highlight CATL’s commitment to not just maintaining its leadership but also fostering innovation across the global EV ecosystem.

Empowering New Players in the EV Market

One of the most exciting prospects of the Panshi chassis is its potential to democratize EV manufacturing. By drastically reducing production costs, this technology paves the way for new entrants in economies without established carmakers.

Robin Zeng elaborated on this vision, stating that the Panshi chassis could make it feasible for niche EV firms to achieve profitability with minimal sales volumes. This opens the door for emerging markets and startups to compete on a global scale, further accelerating the transition to sustainable mobility.

Beyond EVs: Expanding Horizons

CATL’s ambitions don’t stop at the Panshi chassis. The company is also exploring innovative solutions like micro power grids and a battery swapping service, aiming to address broader energy challenges and enhance EV adoption. These initiatives reflect CATL’s holistic approach to building a sustainable future.

The unveiling of the Panshi chassis marks a pivotal moment in the EV industry. CATL is not just reshaping EV manufacturing, but also setting the stage for a new era of mobility. Whether it’s the latest collaborations with luxury brands, or enabling new safety standards in EV cars, CATL’s vision for the future is bold, inclusive, and innovative.