Imagine a technology so transformative that it redefines how we produce one of the most essential materials in modern society: steel. For over a decade, teams of dedicated researchers in China have been perfecting a process that could revolutionize the steel manufacturing industry. Their breakthrough, known as flash ironmaking, is not only astonishing in its speed but also critical for environmental sustainability. This method could soon make traditional blast furnaces seem like relics of the past.

Let’s take a closer look at this technological marvel, its implications for China’s steel industry, and how it could reshape global manufacturing.

A Spark Ignites a Revolution

In the heart of China’s research labs, a team led by Professor Zhang Wenhai from the prestigious Chinese Academy of Engineering has developed a technique that injects finely ground iron ore powder into a blazing hot furnace. This triggers what engineers describe as an “explosive chemical reaction.”

Picture this: bright red, molten iron droplets, glowing with intensity, raining down and pooling at the bottom of the furnace. The result? A stream of high-purity iron ready for casting or “one-step steelmaking.” This entire process takes just 3 to 6 seconds, a staggering contrast to the 5 to 6 hours required by traditional blast furnaces. That’s a speed increase of up to 3,600-fold, reported SCMP, a leading online news publisher from China

Why Flash Ironmaking is a Game-Changer

Faster and More Efficient

Time is money, and flash ironmaking delivers iron at unprecedented speeds. Where traditional methods take hours, this new technique slashes production time to mere seconds. This means more steel can be produced in a shorter period, improving efficiency and reducing operational costs.

Solving the Ore Problem

China, despite being a steel giant, relies heavily on importing high-yield iron ores from countries like Australia, Brazil, and Africa. Traditional methods demand high-grade ores, making the nation vulnerable to international supply chain disruptions.

Flash ironmaking, however, works remarkably well with low and medium-yield ores, which are abundant within China. This not only reduces dependency on imports but also optimizes the use of domestic resources.

Environmental Benefits: Near-zero emissions

One of the most pressing challenges for the steel industry is its environmental footprint. Traditional blast furnaces consume vast amounts of coke (derived from coal), making steel production a significant contributor to carbon dioxide emissions.

Flash ironmaking eliminates the need for coal entirely, paving the way for “near-zero carbon dioxide emissions.”According to Professor Zhang’s calculations, this technology could improve energy efficiency in China’s steel industry by over one-third.

The Technical Marvel: The Ore-Spraying Lance

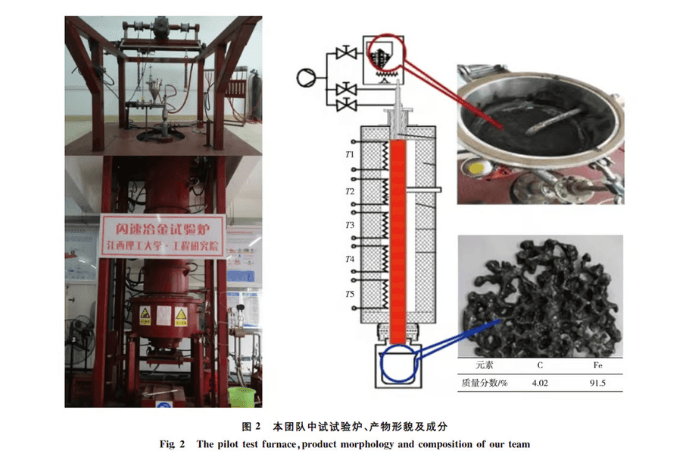

At the heart of this breakthrough is a critical piece of equipment: the ore-spraying lance. To initiate the rapid chemical reaction, iron ore needs to be finely dispersed in a high-temperature, high-reducibility environment.

Zhang’s team has perfected a vortex lance capable of injecting up to 450 tonnes of iron ore particles per hour. To put this into perspective, a reactor with just three lances can produce an astonishing 7.11 million tonnes of iron annually. This lance has already moved into commercial production, marking a major milestone for industrial deployment.

Zhang Wenhai: The Visionary Behind the Innovation

Professor Zhang Wenhai’s journey with flash smelting technology began in the 1970s when he applied the concept to large-scale copper production. His groundbreaking work earned him the first prize in the National Science and Technology Progress Award in 2000 and a prestigious election to the Chinese Academy of Engineering in 2003.

Today, China accounts for nearly 60% of global copper consumption, a testament to Zhang’s enduring impact on the industry. Though the idea of flash ironmaking originated in the United States, it was Zhang’s team that perfected the method, obtaining a patent in 2013 and dedicating the next decade to refining the process.

China’s Steel Dominance and the Road Ahead

China’s steel production capacity already surpasses the combined output of the rest of the world. This dominance fuels key industries such as high-speed rail, shipbuilding, and automobile manufacturing. Yet, the reliance on traditional blast furnaces and heavy consumers of coal has remained a barrier to achieving the country’s ambitious carbon neutrality goals.

Flash ironmaking offers a way forward. By transitioning to this new technology, China can maintain its industrial leadership while drastically cutting emissions.

A Historical Legacy of Ironmaking

China’s pioneering spirit in iron and steel production dates back centuries. As the Tang dynasty poet Li Bai once wrote, the glow from ironmaking furnaces in Anhui Province lit up the night sky. According to an estimate by American historian Robert Hartwell, during the Song dynasty in the 11th century, China’s annual iron production reached 150,000 tonnes. This legacy of innovation continues today. Flash ironmaking could be the next chapter in China’s rich history of metallurgical excellence.

A Greener, Faster Future for Steel

Flash ironmaking is more than a scientific achievement, it’s a potential revolution in global steel production. Faster, cleaner, and more resource-efficient, this technology could redefine how the world approaches ironmaking. By embracing this method, China not only secures its industrial future but also takes a giant leap toward sustainable manufacturing.